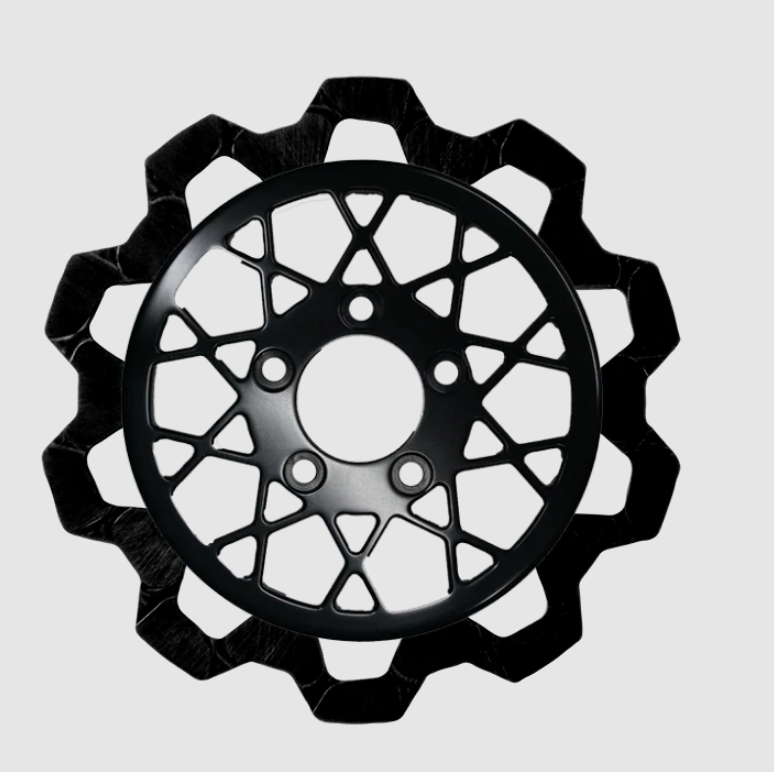

11.8 ” Bow-Tie Cut Gemini Rotor – Front – Anodized Black

$530.00 Original price was: $530.00.$487.60Current price is: $487.60.

$487.60

Lyndall Rotors

Our full-floating, high-carbon steel rotors are CNC machined to exacting tolerances right here in the USA. Lyndall rotors are meticulously designed and thoroughly tested to ensure maximum performance in the most extreme environments and conditions known to powersports. We are so confident in our choice of design, materials and method of manufacturing that we guarantee our rotors for the life of your bike (when used exclusively with our premium quality organic brake pads.)

Our lug-drive rotors feature a highly advanced three-piece design, consisting of three components.

- Outer friction ring (wear surface)

- Inner carrier center (aesthetic portion)

- Helical retaining ring that securely fastens the friction ring to the carrier center in a way that prevents our floating rotor from becoming loose or noisy after the course of its service life.

Lyndall rotors are available in the following sizes to fit all Harley-Davidson models, and will work as a bolt-on replacement:

- 11.5″ x 5mm

- 11.8″ x 5mm

- 11.8″ x 7mm (touring and V-Rod rear)

- 11.5″ x 6mm (M8 Softail rear)

- 13″ x 5mm

Our rotors have a 5 x 3.25″ bolt pattern, excluding Enforcer, Dyna (Low and S) / V-Rod, and V-Rod rear.

Note: If you are purchasing a gold Lyndall rotor, we recommend you use Lyndall Gold Plus or Z plus brake pads to protect the gold finish finish. When using a black Lyndall rotor, you must use Z Plus pads to keep the black finish on the friction surface.

For rotors for pre 2000 Harley-Davidson models, call us at 800-400-9490. (Pre 2000 Harley-Davidson rotors require an adapter ring in the center hole of the rotor to make the center hole diameter 1.985″. This will accommodate for the 3/4″ axle and Timken bearing.)

ABOUT OUR BOW-TIE CUT

Lyndall Bow-Tie cut rotors are our newest design. These are similar to the Crown Cut design, but with significantly less weight and better outgassing. Our Bow-Tie cut friction rings are also designed to provide better stopping power. By reducing the surface area where the brake pads make contact with the friction ring, clamping power per square inch is increased.

| Delivery Time | MTO |

|---|

Q & A

Bike Fitment

List of bikes that fit this product

| Year | Make | Model |

|---|---|---|

| Year | Make | Model |

| 2008 | Harley Davidson | Touring Electra Glide Classic FLHTC |

| 2008 | Harley Davidson | Touring Electra Glide Standard FLHT |

| 2008 | Harley Davidson | Touring Road Glide FLTR |

| 2008 | Harley Davidson | Touring Road King Classic FLHRC |

| 2008 | Harley Davidson | Touring Road King FLHR |

| 2008 | Harley Davidson | Touring Road King Screamin Eagle FLHRSE4 |

| 2008 | Harley Davidson | Touring Street Glide FLHX |

| 2008 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2008 | Harley Davidson | Touring Ultra/Electra Screamin Eagle FLHTCUSE3 |

| 2009 | Harley Davidson | Touring Electra Glide Classic FLHTC |

| 2009 | Harley Davidson | Touring Electra Glide Standard FLHT |

| 2009 | Harley Davidson | Touring Road Glide FLTR |

| 2009 | Harley Davidson | Touring Road Glide Screamin Eagle FLTRSE3 |

| 2009 | Harley Davidson | Touring Road King Classic FLHRC |

| 2009 | Harley Davidson | Touring Road King FLHR |

| 2009 | Harley Davidson | Touring Street Glide FLHX |

| 2009 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2009 | Harley Davidson | Touring Ultra/Electra Screamin Eagle FLHTCUSE4 |

| 2010 | Harley Davidson | Touring Electra Glide Classic FLHTC |

| 2010 | Harley Davidson | Touring Electra Glide Ultra Limited FLHTK |

| 2010 | Harley Davidson | Touring Road Glide Custom FLTRX |

| 2010 | Harley Davidson | Touring Road King Classic FLHRC |

| 2010 | Harley Davidson | Touring Road King FLHR |

| 2010 | Harley Davidson | Touring Street Glide FLHX |

| 2010 | Harley Davidson | Touring Street Glide Screamin Eagle FLHXSE |

| 2010 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2010 | Harley Davidson | Touring Ultra/Electra Screamin Eagle Dark Side Limited FLH |

| 2010 | Harley Davidson | Touring Ultra/Electra Screamin Eagle FLHTCUSE5 |

| 2011 | Harley Davidson | Touring Electra Glide Classic FLHTC |

| 2011 | Harley Davidson | Touring Road Glide Custom FLTRX |

| 2011 | Harley Davidson | Touring Road Glide Ultra FLTRU |

| 2011 | Harley Davidson | Touring Road Glide Ultra Screamin Eagle FLTRUSE |

| 2011 | Harley Davidson | Touring Road King Classic FLHRC |

| 2011 | Harley Davidson | Touring Road King FLHR |

| 2011 | Harley Davidson | Touring Street Glide FLHX |

| 2011 | Harley Davidson | Touring Street Glide Screamin Eagle FLHXSE2 |

| 2011 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2011 | Harley Davidson | Touring Ultra/Electra Limited FLHTK |

| 2011 | Harley Davidson | Touring Ultra/Electra Screamin Eagle FLHTCUSE6 |

| 2012 | Harley Davidson | Touring Electra Glide Classic FLHTC |

| 2012 | Harley Davidson | Touring Road Glide Custom FLTRX |

| 2012 | Harley Davidson | Touring Road Glide Custom Screamin Eagle FLTRXSE |

| 2012 | Harley Davidson | Touring Road Glide Ultra FLTRU |

| 2012 | Harley Davidson | Touring Road King Classic FLHRC |

| 2012 | Harley Davidson | Touring Road King FLHR |

| 2012 | Harley Davidson | Touring Street Glide FLHX |

| 2012 | Harley Davidson | Touring Street Glide Screamin Eagle FLHXSE3 |

| 2012 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2012 | Harley Davidson | Touring Ultra/Electra Limited FLHTK |

| 2012 | Harley Davidson | Touring Ultra/Electra Screamin Eagle FLHTCUSE7 |

| 2013 | Harley Davidson | Touring Electra Glide Classic FLHTC |

| 2013 | Harley Davidson | Touring Road Glide Custom FLTRX |

| 2013 | Harley Davidson | Touring Road Glide Custom Screamin Eagle FLTRXSE2 |

| 2013 | Harley Davidson | Touring Road Glide Ultra FLTRU |

| 2013 | Harley Davidson | Touring Road king Classic FLHRC |

| 2013 | Harley Davidson | Touring Road king FLHR |

| 2013 | Harley Davidson | Touring Road King Screamin Eagle FLHRSE5 |

| 2013 | Harley Davidson | Touring Street Glide FLHX |

| 2013 | Harley Davidson | Touring Tri Glide Ultra Classic FLHTCUTG |

| 2013 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2013 | Harley Davidson | Touring Ultra/Electra Limited FLHTK |

| 2013 | Harley Davidson | Touring Ultra/Electra Screamin Eagle FLHTCUSE8 |

| 2014 | Harley Davidson | Touring Road King FLHR |

| 2014 | Harley Davidson | Touring Street Glide FLHX |

| 2014 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2014 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2014 | Harley Davidson | Touring Ultra/Electra Limited FLHTK |

| 2015 | Harley Davidson | Touring Road Glide FLTRX |

| 2015 | Harley Davidson | Touring Road Glide Special FLTRXS |

| 2015 | Harley Davidson | Touring Road Glide Ultra Screamin Eagle FLTRUSE |

| 2015 | Harley Davidson | Touring Road King FLHR |

| 2015 | Harley Davidson | Touring Street Glide FLHX |

| 2015 | Harley Davidson | Touring Street Glide Screamin Eagle FLHXSE |

| 2015 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2015 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2015 | Harley Davidson | Touring Ultra/Electra Limited FLHTK |

| 2015 | Harley Davidson | Touring Ultra/Electra Limited Low FLHTKL |

| 2015 | Harley Davidson | Touring Ultra/Electra Low FLHTCUL |

| 2016 | Harley Davidson | Touring Road Glide FLTRX |

| 2016 | Harley Davidson | Touring Road Glide Special FLTRXS |

| 2016 | Harley Davidson | Touring Road Glide Ultra Screamin Eagle FLTRUSE |

| 2016 | Harley Davidson | Touring Road King FLHR |

| 2016 | Harley Davidson | Touring Street Glide FLHX |

| 2016 | Harley Davidson | Touring Street Glide Screamin Eagle FLHXSE |

| 2016 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2016 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2016 | Harley Davidson | Touring Ultra/Electra Limited CVO FLHTKSE |

| 2016 | Harley Davidson | Touring Ultra/Electra Limited FLHTK |

| 2016 | Harley Davidson | Touring Ultra/Electra Limited Low FLHTKL |

| 2016 | Harley Davidson | Touring Ultra/Electra Low FLHTCUL |

| 2017 | Harley Davidson | Touring Road Glide FLTRX |

| 2017 | Harley Davidson | Touring Road Glide Special FLTRXS |

| 2017 | Harley Davidson | Touring Road Glide Ultra FLTRU |

| 2017 | Harley Davidson | Touring Road King FLHR |

| 2017 | Harley Davidson | Touring Street Glide FLHX |

| 2017 | Harley Davidson | Touring Street Glide Screamin Eagle FLHXSE |

| 2017 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2017 | Harley Davidson | Touring Ultra/Electra FLHTCU |

| 2017 | Harley Davidson | Touring Ultra/Electra Limited CVO FLHTKSE |

| 2017 | Harley Davidson | Touring Ultra/Electra Limited FLHTK |

| 2017 | Harley Davidson | Touring Ultra/Electra Limited Low FLHTKL |

| 2018 | Harley Davidson | Touring Electra Glide Ultra Classic FLHTCU |

| 2018 | Harley Davidson | Touring Road Glide CVO FLTRXSE |

| 2018 | Harley Davidson | Touring Road Glide FLTRX |

| 2018 | Harley Davidson | Touring Road Glide Special FLTRXS |

| 2018 | Harley Davidson | Touring Road Glide Ultra FLTRU |

| 2018 | Harley Davidson | Touring Road King FLHR |

| 2018 | Harley Davidson | Touring Road King Special FLHRXS |

| 2018 | Harley Davidson | Touring Street Glide CVO FLHXSE |

| 2018 | Harley Davidson | Touring Street Glide FLHX |

| 2018 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2018 | Harley Davidson | Touring Ultra Limited CVO FLHTKSE |

| 2018 | Harley Davidson | Touring Ultra Limited FLHTK |

| 2018 | Harley Davidson | Touring Ultra Limited Low FLHTKL |

| 2019 | Harley Davidson | Touring Electra Glide Ultra Classic FLHTCU |

| 2019 | Harley Davidson | Touring Road Glide CVO FLTRXSE |

| 2019 | Harley Davidson | Touring Road Glide FLTRX |

| 2019 | Harley Davidson | Touring Road Glide Special FLTRXS |

| 2019 | Harley Davidson | Touring Road Glide Ultra FLTRU |

| 2019 | Harley Davidson | Touring Road King FLHR |

| 2019 | Harley Davidson | Touring Road King Special FLHRXS |

| 2019 | Harley Davidson | Touring Street Glide CVO FLHXSE |

| 2019 | Harley Davidson | Touring Street Glide FLHX |

| 2019 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2019 | Harley Davidson | Touring Ultra Limited CVO FLHTKSE |

| 2019 | Harley Davidson | Touring Ultra Limited FLHTK |

| 2019 | Harley Davidson | Touring Ultra Limited Low FLHTKL |

| 2020 | Harley Davidson | Touring Electra Glide Standard FLHT |

| 2020 | Harley Davidson | Touring Electra Glide Ultra Limited CVO FLHTKSE |

| 2020 | Harley Davidson | Touring Electra Glide Ultra Limited FLHTK |

| 2020 | Harley Davidson | Touring Road Glide FLTRX |

| 2020 | Harley Davidson | Touring Road Glide Limited FLTRK |

| 2020 | Harley Davidson | Touring Road Glide Special FLTRXS |

| 2020 | Harley Davidson | Touring Road King FLHR |

| 2020 | Harley Davidson | Touring Road King Special FLHRXS |

| 2020 | Harley Davidson | Touring Street Glide CVO FLHXSE |

| 2020 | Harley Davidson | Touring Street Glide FLHX |

| 2020 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2021 | Harley Davidson | Touring Electra Glide Police FLHTP |

| 2021 | Harley Davidson | Touring Electra Glide Revival FLH |

| 2021 | Harley Davidson | Touring Electra Glide Standard FLHT |

| 2021 | Harley Davidson | Touring Road Glide CVO FLTRXSE |

| 2021 | Harley Davidson | Touring Road Glide FLTRX |

| 2021 | Harley Davidson | Touring Road Glide Limited FLTRK |

| 2021 | Harley Davidson | Touring Road Glide Special FLTRXS |

| 2021 | Harley Davidson | Touring Road King FLHR |

| 2021 | Harley Davidson | Touring Road King Police FLHP |

| 2021 | Harley Davidson | Touring Road King Special FLHRXS |

| 2021 | Harley Davidson | Touring Street Glide CVO FLHXSE |

| 2021 | Harley Davidson | Touring Street Glide FLHX |

| 2021 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2021 | Harley Davidson | Touring Ultra Limited CVO FLHTKSE |

| 2021 | Harley Davidson | Touring Ultra Limited FLHTK |

| 2022 | Harley Davidson | Touring Electra Glide Police FLHTP |

| 2022 | Harley Davidson | Touring Electra Glide Standard FLHT |

| 2022 | Harley Davidson | Touring Road Glide CVO FLTRXSE |

| 2022 | Harley Davidson | Touring Road Glide FLTRX |

| 2022 | Harley Davidson | Touring Road Glide FLTRXST |

| 2022 | Harley Davidson | Touring Road Glide Limited CVO FLTRK |

| 2022 | Harley Davidson | Touring Road Glide Limited FLTRK |

| 2022 | Harley Davidson | Touring Road Glide Special FLTRXS |

| 2022 | Harley Davidson | Touring Road King FLHR |

| 2022 | Harley Davidson | Touring Road King Police FLHP |

| 2022 | Harley Davidson | Touring Road King Special FLHRXS |

| 2022 | Harley Davidson | Touring Street Glide CVO FLHXSE |

| 2022 | Harley Davidson | Touring Street Glide FLHX |

| 2022 | Harley Davidson | Touring Street Glide FLHXST |

| 2022 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2022 | Harley Davidson | Touring Ultra Limited FLHTK |

| 2023 | Harley Davidson | Touring Electra Glide Highway King FLHFB |

| 2023 | Harley Davidson | Touring Electra Glide Ultra Limited FLHTK |

| 2023 | Harley Davidson | Touring Road Glide CVO/SE FLTRXSE |

| 2023 | Harley Davidson | Touring Road Glide FLTRX |

| 2023 | Harley Davidson | Touring Road Glide Limited CVO FLTRKSE |

| 2023 | Harley Davidson | Touring Road Glide Limited FLTRK |

| 2023 | Harley Davidson | Touring Road Glide Special FLTRXS |

| 2023 | Harley Davidson | Touring Road Glide ST FLTRXST |

| 2023 | Harley Davidson | Touring Road King Special FLHRXS |

| 2023 | Harley Davidson | Touring Street Glide CVO/SE FLHXSE |

| 2023 | Harley Davidson | Touring Street Glide FLHX |

| 2023 | Harley Davidson | Touring Street Glide Special FLHXS |

| 2023 | Harley Davidson | Touring Street Glide ST FLHXST |

| 2024 | Harley Davidson | Touring Electra Glide Ultra Limited FLHTK |

| 2024 | Harley Davidson | Touring Road Glide CVO SE FLTRXSE |

| 2024 | Harley Davidson | Touring Road Glide CVO ST FLTRXSTSE |

| 2024 | Harley Davidson | Touring Road Glide FLTRX |

| 2024 | Harley Davidson | Touring Road Glide Limited FLTRK |

| 2024 | Harley Davidson | Touring Road King Special FLHRXS |

| 2024 | Harley Davidson | Touring Street Glide CVO SE FLHXSE |

| 2024 | Harley Davidson | Touring Street Glide FLHX |

| 2025 | Harley Davidson | Touring Road Glide CVO SE FLTRXSE |

| 2025 | Harley Davidson | Touring Road Glide CVO ST FLTRXSTSE |

| 2025 | Harley Davidson | Touring Road Glide FLTRX |

| 2025 | Harley Davidson | Touring Road King Special FLHRXS |

| 2025 | Harley Davidson | Touring Street Glide CVO SE FLHXSE |

| 2025 | Harley Davidson | Touring Street Glide FLHX |

| 2025 | Harley Davidson | Touring Street Glide Ultra FLHXU |

Other Items You May Like

Related products

-

Brake Rotors

Pair of Racelite Series Touch of Color Red Enforcer Front Rotors, 2008-2023 Touring

Rated 0 out of 5$998.00Original price was: $998.00.$918.16Current price is: $918.16. Buy Now! -

Brake Rotors

Super Spoke Rear Zinc Black 11.8 Rotor Disc Harley Touring Dyna Softail

Rated 0 out of 5$139.95Original price was: $139.95.$128.75Current price is: $128.75. Buy Now! -

Brake Rotors

Super Spoke Rear Polished 11.5 Rotor Disc Harley Touring Dyna Softail

Rated 0 out of 5$139.95Original price was: $139.95.$128.75Current price is: $128.75. Buy Now! -

Brake Rotors

Pair of Racelite Series Touch of Color Blue Enforcer Front Rotors, 2008-2023 Touring

Rated 0 out of 5$998.00Original price was: $998.00.$918.16Current price is: $918.16. Buy Now!